320 Ton Press Brake Machines are a powerful tool for the metalworking industry, providing superior performance and reliability. These machines offer a variety of benefits to manufacturers and fabricators, including increased productivity, improved safety, and enhanced accuracy. This article provides a comprehensive overview of the advantages of using a 320 Ton Press Brake Machine, including improved accuracy, increased flexibility, faster production times, and improved safety features. Additionally, this article outlines the various features and capabilities of these machines to help users understand their potential applications.

Key Design Considerations for 320 Ton Press Brake Machines

Design considerations for 320 ton press brake machines are essential to ensure safe, accurate and efficient operation of these powerful tools. With a range of models available, from 90 ton press brake machines to 100 ton hydraulic press brake machines, it is important to understand the design considerations that can impact performance.

The most important design consideration for press brake machines is the maximum capacity of the machine, which is determined by the size of the workpiece that can be bent with the machine. The 320 ton press brake machine has a capacity of 3/8” thick steel plate at full stroke. This capacity can vary depending on the manufacturer and type of machine being used.

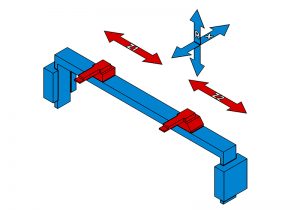

The next consideration is the length of stroke, or distance between the back gauge and ram, which determines how long a part can be bent with a given machine. The 320 ton press brake machine has a stroke length of 36”, which allows for parts up to 36” long to be bent with the machine. This length can vary depending on the manufacturer and type of machine being used.

The next consideration is the amount of bending force that can be applied to a part during bending. The 320 ton press brake machine has a maximum force rating of 25 tons per foot, which allows for parts up to 3/8” thick steel plate to be bent without exceeding this rating. This force rating can vary depending on the manufacturer and type of machine being used.

The final consideration is accuracy, which is determined by both the design and build quality of the machine as well as its operating environment. The 320 ton press brake machine has an accuracy rating of +/- 0.004” over 36”, allowing for parts up to 3/8” thick steel plate to be bent with precision and repeatability. This accuracy rating can vary depending on the manufacturer and type of machine being used.

Overall, when selecting a 320 ton press brake machine it is important to consider all aspects of its design in order to ensure safe, accurate and efficient operation. From capacity and stroke length to bending force and accuracy ratings, these considerations will help ensure that any plate press brake machine meets your specific needs and requirements.

Advantages of 320 Ton Press Brake Machines over Other Bending Solutions

The 320 Ton Press Brake Machine is a high-end bending solution that offers numerous advantages over other types of press brake machines, such as 90 ton and 100 ton hydraulic press brakes, and plate press brake machines.

The most obvious advantage of the 320 Ton Press Brake Machine is its sheer power. This press brake machine is able to generate up to 320 tons of force, which is more than double the amount of force generated by 90 ton and 100 ton hydraulic press brakes. This allows the machine to bend thicker and harder materials with greater precision and accuracy. Additionally, the machine's large capacity makes it suitable for a variety of applications, from simple sheet metal bending to more complex projects requiring higher levels of accuracy and precision.

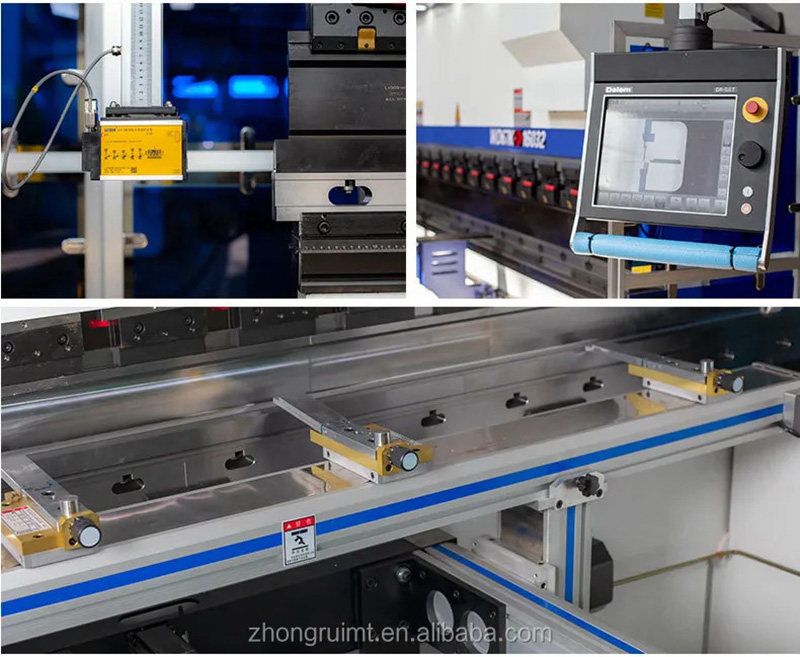

Another advantage of the 320 Ton Press Brake Machine is its user-friendly design. The machine is equipped with a touchscreen control panel that allows users to easily program and adjust bending parameters with just a few taps. This makes it much easier for users to adjust settings for different materials and projects. Additionally, the machine features an intuitive graphical user interface that makes it easy for users to access all the necessary functions without having to refer to a manual or instruction book.

Finally, the 320 Ton Press Brake Machine is also highly reliable and efficient. The machine has been designed for long-term use, so it can be expected to last for many years without needing major repairs or replacements. Furthermore, its advanced motor technology ensures that it runs smoothly and efficiently without any major problems. This ensures that users can count on consistent performance from this machine over time.

In conclusion, the 320 Ton Press Brake Machine offers numerous advantages over other types of press brake machines, including its powerful force output, user-friendly design, and reliable performance. It is therefore an ideal choice for any business looking for a high-end bending solution that can handle any project with precision and accuracy.

The Impact of Hydraulic Power on Performance and Accuracy of 320 Ton Press Brake Machines

Hydraulic power is a critical factor when it comes to performance and accuracy of press brake machines. In particular, the 320 ton press brake machine is highly dependent on the quality of its hydraulic system. This type of machine is typically used to bend sheet metal into complex shapes, so precision is essential.

A typical 320 ton press brake machine utilizes a 90 ton hydraulic press brake to exert pressure on the sheet metal. The hydraulic system in the 90 ton press brake provides the necessary force to bend the material. This force must be precise and consistent in order to ensure accuracy and repeatability of the bends. The hydraulic system also helps to minimize vibrations during operation, which can cause irregularities in the final product.

The quality of the hydraulic power also affects other aspects of performance such as speed and productivity. The higher the pressure exerted by the 90 ton press brake, the faster it can complete a job. The faster speed enables more jobs to be completed in less time, thus increasing productivity.

In addition, hydraulic power also impacts accuracy when it comes to plate press brake machines. Plate press brakes are used to form large sheets of metal into specific shapes or profiles with extreme precision. The accuracy of these machines depends heavily on their hydraulic systems because they must maintain consistent pressure throughout each bending cycle in order to produce accurate results.

Finally, high-quality hydraulic power helps increase safety by preventing overstressing or damaging parts during operation. This is especially important when it comes to heavy-duty machines like 320 ton press brakes, as these are typically used for industrial applications where safety is paramount.

In conclusion, hydraulic power plays an important role in performance and accuracy when it comes to 320 ton press brake machines. Quality hydraulic systems provide consistent pressure for precise bending results and faster speeds for increased productivity. They also help ensure safety by preventing overstressing or damaging parts during operation. As such, investing in a high-quality hydraulic system for your 320 ton press brake is essential for achieving maximum performance and accuracy from your machine.

Cost-Saving Benefits of 320 Ton Press Brake Machines

The 320 Ton Press Brake Machine is an industrial grade piece of equipment that offers powerful and reliable performance for a wide range of applications. This machine is equipped with a high-speed, dual-axis drive system, allowing for quick and accurate bending operations. It also features a heavy-duty construction that is designed to withstand the rigors of daily use. The 320 Ton Press Brake Machine offers cost savings benefits for industrial and manufacturing operations.

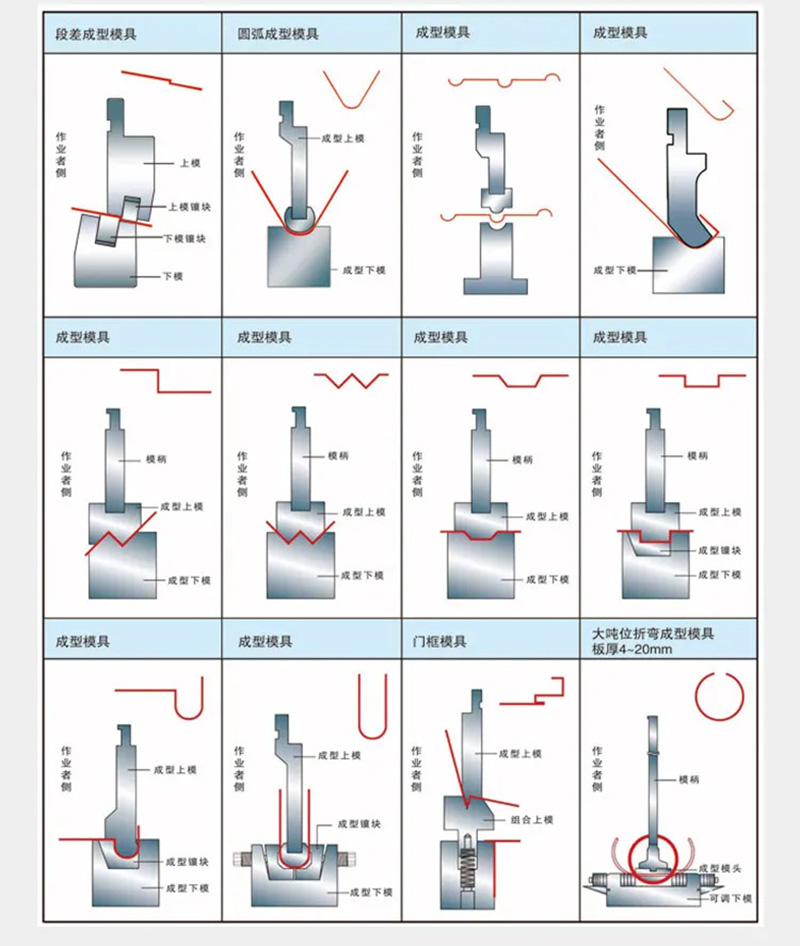

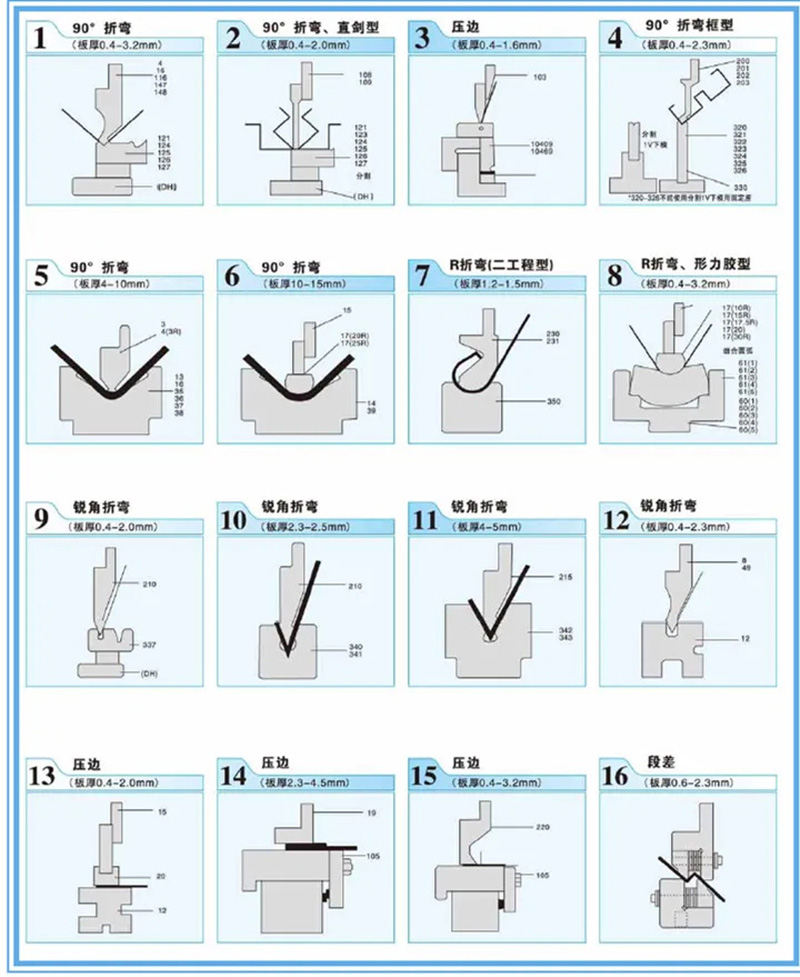

The 320 Ton Press Brake Machine features a robust design that is capable of handling large workpieces with ease. Its powerful drive system enables it to bend even the toughest of metals without difficulty, while its rigid construction ensures long-term reliability and stability. The machine also features a variety of tooling options, including standard punches, dies, and angle tools, that can be used to customize the bending process to meet specific requirements. Additionally, its user-friendly controls make it easy to set up and operate the machine, allowing users to quickly switch between jobs without having to reset the machine each time.

In addition to its robust design and easy-to-use controls, the 320 Ton Press Brake Machine also offers cost savings benefits compared to smaller machines such as 90 ton press brakes or 100 ton hydraulic press brakes. By utilizing this larger capacity press brake machine, industrial operations can reduce their energy consumption while still achieving their desired results. Furthermore, because this machine is capable of handling larger plates than smaller press brakes, it can help reduce labor costs by reducing the need for multiple passes on larger projects. Lastly, because of its heavy-duty construction and long-term reliability, the 320 Ton Press Brake Machine has a significantly lower cost of ownership than other plate press brake machines in its class.

Safety Features of 320 Ton Press Brake Machines

A 320 Ton Press Brake Machine is a powerful and precise machine designed to form metal sheets and plates into shapes. It is a large-scale hydraulic press brake machine that is used in metalworking and sheet metal fabrication. This machine has a range of safety features designed to protect operators and ensure that the process is conducted safely and efficiently.

The first safety feature is the emergency stop button which allows operators to quickly stop the machine in case of an emergency or accident. The button can be easily located, allowing for quick action in the event of an emergency. The machine also has a pressure relief valve which prevents over-pressurization of the hydraulic system, ensuring that the press brake does not exceed its operating limits.

The machine also has a full-body guard made of durable steel or aluminum which surrounds the entire press brake and protects operators from contact with moving parts or hot metal. This guard also prevents dust, debris, or other materials from entering the working area. Additionally, the guard also serves as a safety shield to protect operators from high-pressure fluids or sparks that may be emitted during operation.

The machine also has a foot pedal control which allows operators to control the speed and force of the press brake without having to use their hands. This ensures that operators can keep their hands away from any potentially hazardous areas while still maintaining control over the process. Finally, the press brake is equipped with sensors that detect if any foreign objects are present in the working area and will automatically shut off if something dangerous is detected.

The 320 Ton Press Brake Machine is a powerful and precise tool used in metalworking and sheet metal fabrication. Its range of safety features ensures that it can be operated safely and efficiently, providing optimal results for any job. It is important for operators to be aware of these safety features and ensure that they are being used properly in order to prevent any accidents or injuries.

Installation and Maintenance Requirements for 320 Ton Press Brake Machines

Installation and maintenance of 320 ton press brake machines is an important part of owning and operating the machine. Proper installation and maintenance can help ensure the long-term reliability and safety of the machine, while ensuring that it produces quality parts with minimal downtime.

Installation of a 320 ton press brake should be done by a qualified technician. Before installation, the area should be checked to ensure that it is suitable for the machine. The floor must be strong enough to support the weight of the machine, and the power requirements must be met. It is also important to make sure that there is adequate space around the machine for easy access and operation.

Once the area is ready, the technician will install the machine according to manufacturer’s instructions. This includes mounting it on a solid foundation, making sure that all electrical connections are properly connected, connecting any necessary hoses or pipes, and adjusting the machine to ensure proper operation. The technician will also check for any signs of wear or damage, and make any necessary repairs or replacements before putting the machine into operation.

Maintenance of a 320 ton press brake should be done on a regular basis. This includes regular inspections for wear or damage, cleaning and lubricating all moving parts, checking for proper alignment and tensioning of belts and pulleys, testing safety systems, and replacing worn out components as necessary. It is also important to keep records of maintenance activities in order to ensure that all components are functioning properly over time.

In addition to regular maintenance activities, it is important to keep spare parts on hand in case of emergency repairs or replacements. Common spare parts include brakes, blades, dies, pins, screws, nuts, bolts, washers, springs, and other small components that can be easily replaced if needed. Having these items on hand can help minimize downtime when repairs are needed.

When purchasing a 320 ton press brake machine, it is important to select one from a reputable manufacturer that provides good customer service and reliable parts availability. This will help ensure that your machine is well-maintained over time and produces quality parts with minimal downtime. Additionally, it is also important to consider other press brake machines such as 90 ton press brakes and 100 ton hydraulic press brakes in order to find one that best meets your needs in terms of size and capacity. Plate press brake machines can also be used for heavier projects where higher capacity is needed.

Conclusion

In conclusion, 320 ton press brake machines offer numerous benefits to any business that requires bending, forming and shaping metal components. These machines provide high accuracy, speed and repeatability with their servo-driven systems, enabling them to produce complex parts quickly and with minimal waste. Additionally, their precision technology allows for quick tooling changes and simple programming for quick job setup. With their improved safety features, 320 ton press brake machines are an ideal choice for businesses looking to improve their production process.