Introduction

Press brakes are essential tools in metal fabrication, offering precision and accuracy in the bending of metal sheets and plates. When choosing a press brake, it's crucial to select the right tonnage to suit your specific requirements. In this guide, we'll be focusing on 90 ton press brakes, a popular choice for many metal fabrication projects.

A press brake is a machine tool that uses a ram to apply pressure to metal sheets and plates, forming them into specific shapes and angles. Tonnage refers to the maximum amount of force that a press brake can exert on the metal workpiece. The right tonnage depends on several factors, including the thickness and type of metal being bent, as well as the desired bend radius and angle.

A 90 ton press brake is a versatile machine that offers the perfect balance of power and precision for many metal fabrication projects. Whether you're a small fabrication shop or a large manufacturer, a 90 ton press brake can help you achieve greater efficiency and productivity, as well as improved accuracy and precision in your metal forming processes.

Understanding the basics of 90 ton press brakes

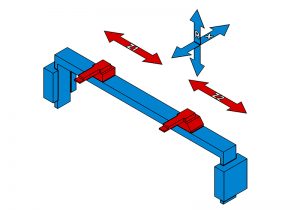

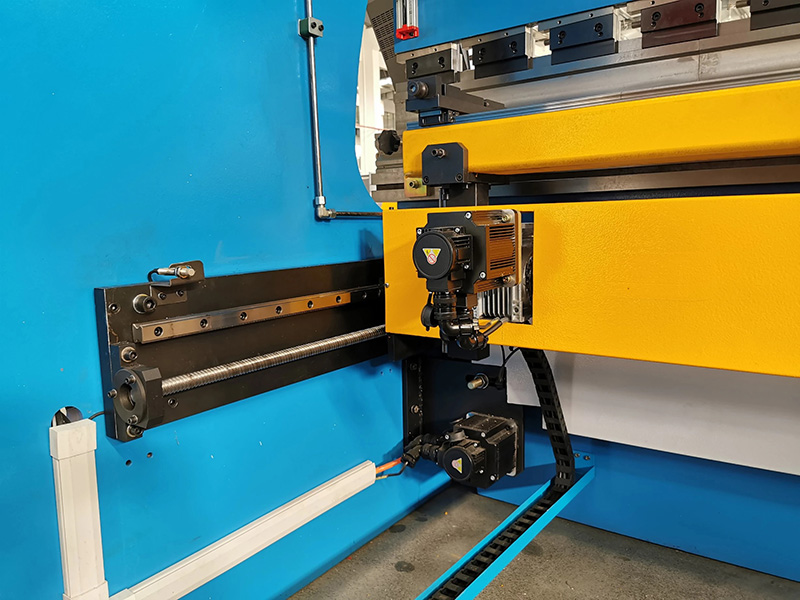

Before diving into the features and benefits of 90 ton press brakes, it's important to understand how they work. A press brake consists of a bed, a ram, and a clamping system. The bed is the main frame of the machine and provides support for the metal workpiece. The ram is a movable component that applies force to the metal, and the clamping system holds the metal securely in place during the bending process.

The working principle of a press brake is relatively simple. The metal workpiece is placed on the bed and held in place by the clamping system. The ram then moves down and applies pressure to the metal, forming it into the desired shape and angle. The amount of pressure applied by the ram is controlled by a hydraulic system, which is driven by a motor.

It's important to note that press brakes are precision tools that require proper training and experience to operate safely and effectively. An operator must have a good understanding of the machine's capabilities and limitations, as well as the properties of the metal being formed, in order to achieve the desired results.

Key Features of 90 ton press brakes

A 90 ton press brake offers several key features that make it an attractive choice for many metal fabrication projects. Some of the most important features to consider include tonnage and bend length, ram stroke and throat depth, motor power and speed, and control system and safety features.

Tonnage and bend length are two of the most important factors to consider when choosing a press brake. The tonnage determines the maximum amount of force that can be applied to the metal, while the bend length determines the maximum length of the metal workpiece that can be bent in one pass. A 90 ton press brake typically offers a bend length of around 6 feet, which is suitable for most small to medium-sized projects.

The ram stroke and throat depth of a 90 ton press brake also play an important role in determining its capabilities. The ram stroke refers to the maximum distance that the ram can move, while the throat depth is the distance between the bed and the ram when the ram is in its lowest position. Both of these factors determine the thickness and type of metal that can be formed, as well as the maximum bend radius and angle.

Motor power and speed are also important considerations when choosing a 90 ton press brake. The motor drives the hydraulic system, which in turn controls the movement of the ram. The motor must be powerful enough to generate the necessary force to bend the metal, while also offering a sufficient speed to complete the bend in a timely manner.

Finally, the control system and safety features of a 90 ton press brake are critical for ensuring safe and efficient operation. The control system allows the operator to control the movement of the ram, as well as set and monitor key parameters such as speed, force, and bend angle. Safety features, such as emergency stop buttons and interlocks, help to prevent accidents and protect the operator and machine.

Benefits of using 90 ton press brakes

There are several benefits to using a 90 ton press brake in your metal fabrication projects. Some of the most significant benefits include improved accuracy and precision, increased efficiency and productivity, and greater versatility and flexibility.

One of the primary benefits of using a 90 ton press brake is improved accuracy and precision. The machine's ability to apply a precise amount of force to the metal workpiece, combined with its ability to control the bend angle and radius, results in highly accurate and consistent bends. This can lead to reduced waste and rework, as well as improved product quality and reliability.

Another key benefit of using a 90 ton press brake is increased efficiency and productivity. The machine's hydraulic system allows for fast and efficient bending, allowing you to complete projects in a timely manner. The press brake's ability to handle a wide range of metal thicknesses and types also means that you can complete a wider range of projects with just one machine, reducing the need for multiple tools and increasing your overall productivity.

Finally, a 90 ton press brake offers greater versatility and flexibility. The machine can be configured to meet your specific needs, with various tooling options available for different bending applications. The press brake's ability to bend metal into complex shapes and angles also makes it suitable for a wide range of projects, from simple straight bends to complex geometries.

In conclusion, a 90 ton press brake is a versatile, efficient, and accurate tool that can provide numerous benefits for your metal fabrication projects. Whether you're a small fabrication shop or a large manufacturer, a 90 ton press brake can help you achieve greater success and growth in your business.

Applications of 90 ton press brakes

90 ton press brakes are used in a wide range of metal fabrication applications, from small-scale prototyping to large-scale production runs. Some of the most common applications include forming parts for the automotive and aerospace industries, creating metal brackets and brackets, and producing custom metal products for various industries.

In the automotive industry, 90 ton press brakes are often used to form metal parts for cars, trucks, and other vehicles. These parts can include body panels, frames, and suspension components, among others. The accuracy and precision of the press brake ensure that these parts are consistent and meet the high standards required by the automotive industry.

The aerospace industry is another area where 90 ton press brakes are frequently used. These machines are used to form metal parts for aircraft, including fuselage sections, wing components, and other critical parts. The ability of the press brake to produce accurate and consistent parts helps to ensure the safety and reliability of aircraft.

In addition to these large industries, 90 ton press brakes are also commonly used by small fabrication shops and manufacturers to produce custom metal products. This can include metal signs, frames, and brackets, among others. The versatility of the press brake makes it an ideal tool for these types of applications, as it can be easily configured to meet the specific needs of each project.

In conclusion, the 90 ton press brake is a highly versatile machine that has a wide range of applications in the metal fabrication industry. Whether you're working in the automotive, aerospace, or another industry, a 90 ton press brake can help you achieve greater success and growth in your business.

Factors to Consider When Purchasing a 90 ton Press Brake

When purchasing a 90 ton press brake, there are several factors that you need to consider to ensure that you are getting the right machine for your needs. Some of the most important factors include the machine's capacity, accuracy and precision, versatility, and ease of use.

One of the key factors to consider when purchasing a 90 ton press brake is the machine's capacity. You need to make sure that the press brake can handle the types of metal and thicknesses that you will be working with. The capacity of the machine is also important if you plan to use it for a wide range of projects, as you want to make sure that it has the capability to handle all of your needs.

Another factor to consider when purchasing a 90 ton press brake is the machine's accuracy and precision. The accuracy of the press brake will affect the quality of the finished product, so it is important to choose a machine that is capable of producing precise and consistent bends. The machine's control systems, such as the hydraulic and backgauge systems, should also be considered when evaluating the machine's accuracy and precision.

The versatility of the 90 ton press brake is also an important factor to consider. The machine should be able to handle a wide range of metal thicknesses and types, and should also have a variety of tooling options available for different bending applications. The machine's ability to bend metal into complex shapes and angles is also a key factor, as it will allow you to complete a wider range of projects with just one machine.

Finally, ease of use is another important factor to consider when purchasing a 90 ton press brake. The machine should be easy to set up, operate, and maintain, with a user-friendly interface and simple controls. The machine's design should also be ergonomic, with features that help to minimize operator fatigue and improve overall safety.

In conclusion, when purchasing a 90 ton press brake, it is important to consider several factors, including the machine's capacity, accuracy and precision, versatility, and ease of use. By carefully evaluating each of these factors, you can ensure that you are purchasing the right machine for your needs and that you are making a smart investment for your business.

Conclusion

The 90 ton press brake is a highly versatile machine that is widely used in the metal fabrication industry for a variety of applications. Whether you're working in the automotive, aerospace, or another industry, a 90 ton press brake can provide you with the accuracy, precision, and versatility you need to get the job done.

When purchasing a 90 ton press brake, it is important to consider several factors, including the machine's capacity, accuracy and precision, versatility, and ease of use. By carefully evaluating each of these factors, you can ensure that you are getting the right machine for your needs and that you are making a smart investment for your business.

In conclusion, a 90 ton press brake is a valuable tool that can help you achieve greater success and growth in your business. Whether you're a small fabrication shop or a large-scale manufacturer, a 90 ton press brake can provide you with the capabilities and performance you need to succeed. So, if you're looking for a machine that can help you achieve greater success in your metal fabrication projects, consider purchasing a 90 ton press brake today!