The use of metal pipe laser cutting machines is becoming increasingly popular in a variety of industries. This comprehensive guide provides an overview of the features and benefits of this technology, as well as important considerations to keep in mind when choosing the right machine for your specific needs. We discuss the different types of machines available, the advantages and disadvantages of each type, and important safety tips to consider. By understanding all these factors, you can make an informed decision about which metal pipe laser cutting machine is best for your business.

Assessing Requirements for Metal Pipe Laser Cutting

When assessing the requirements for metal pipe laser cutting, it is important to consider the material type and size, as well as the desired cut shape. Different types of metal have different properties and will require different cutting parameters. It is also important to consider the size of the pipes, as smaller pipes may require more precision than larger ones. Additionally, the desired cut shape should be taken into consideration; some shapes may require more intricate cutting than others.

The type of laser used for cutting metal pipes will also have an effect on the quality of the finished product. Generally speaking, higher-powered lasers can achieve greater accuracy and faster cutting speeds. For example, a CO2 laser is typically used for most metals, while a fiber laser is often used for stainless steel due to its high precision and speed. The power of the laser should be appropriate for both the material type and thickness being cut.

The choice of gas also plays an important role in metal pipe laser cutting. Depending on the type of material being cut, a variety of gases can be used such as oxygen, nitrogen, argon or helium. Each gas has its own unique properties that affect how it interacts with materials being cut; therefore it is important to select one that is best suited for each application.

Other factors to consider when assessing requirements for metal pipe laser cutting include beam parameters such as spot size and focus length; these determine how focused or dispersed the beam is during cutting operations. Additionally, pulse frequency should also be considered; this affects how quickly a beam moves across a surface and can significantly impact overall productivity levels if set too low or too high.

Finally, safety protocols must always be observed when working with lasers to ensure that all personnel are adequately protected from any potential hazards associated with their use. This includes wearing appropriate protective gear such as eye protection, gloves and face shields when operating a laser cutter or when in close proximity to them during operation.

Analyzing Cost-Effectiveness of Metal Pipe Laser Cutting Machines

The cost-effectiveness of metal pipe laser cutting machines is an important factor in determining their usefulness in industrial and manufacturing operations. Laser cutting is a precise and efficient method of producing parts from sheet metal, and it can be used to cut intricate shapes or complex profiles that would be difficult to produce using traditional methods. In addition, laser cutting eliminates the need for tooling, which can be expensive and time consuming. As such, metal pipe laser cutting machines are often used in production processes where cost-effectiveness is a major consideration.

When analyzing the cost-effectiveness of metal pipe laser cutting machines, several factors should be taken into account. These include the initial purchase price of the machine, as well as any ongoing maintenance costs. Additionally, the type of materials being cut will affect the overall cost-effectiveness of the machine; different materials require different levels of energy input to achieve a given level of accuracy and efficiency. Other factors to consider include the number of parts that can be produced with a single setup, as well as the speed at which parts can be produced with minimal setup time.

The efficiency with which a metal pipe laser cutting machine operates is also an important factor in assessing its cost-effectiveness. A machine that produces quality parts at high speeds and with minimal waste will save money over time due to decreased material costs and reduced labor requirements. Furthermore, if a machine produces accurate cuts with minimal burrs or edges that require additional finishing work, it may save on labor costs associated with post-production finishing processes. Additionally, high quality cuts may allow for improved aesthetics when compared to traditional methods such as sawing or drilling.

Finally, when assessing the cost-effectiveness of metal pipe laser cutting machines it is important to consider environmental considerations such as noise pollution and hazardous waste disposal requirements associated with traditional manufacturing processes that are eliminated by using lasers for production purposes. By reducing energy consumption and eliminating hazardous waste associated with traditional manufacturing processes, lasers can help organizations meet their sustainability goals while still producing quality parts at a reasonable price point.

Understanding Laser Beam Dynamics for Metal Pipe Laser Cutting

Laser beam dynamics for metal pipe laser cutting is a complex and challenging process that requires a deep understanding of the physical processes involved. Laser beam dynamics involve the interactions between light and matter, as well as the various parameters that affect how a laser beam interacts with metal. Laser beam dynamics are essential to the effective use of lasers in metal pipe cutting.

At the most basic level, laser beam dynamics involve controlling the output power, wavelength, pulse duration, and spot size of the laser beam. The output power of the laser determines its ability to cut through material; higher power lasers can cut through thicker materials than lower powered lasers. The wavelength of a laser can also be adjusted to interact differently with different materials; for example, infrared lasers are often used to cut through steel. Pulse duration determines how quickly or slowly the material is melted by the laser; short pulses provide faster cutting speeds while longer pulses provide more controlled cutting speeds. Finally, spot size determines how large or small an area is affected by each pulse; larger spot sizes will cut larger areas but require more energy than smaller spot sizes.

In addition to controlling these fundamental parameters, several other factors must also be taken into account when optimizing laser beam dynamics for metal pipe cutting. These include focusing optics, nozzle geometry, reflectivity of the material being cut, and ambient temperature. Focusing optics affect how efficiently energy is transferred from the laser to the material being cut; nozzle geometry affects how quickly and efficiently gas is evacuated from around the cutting area; reflectivity affects how much of the incident light is absorbed by the material being cut; and ambient temperature affects both cutting speed and quality by affecting heat transfer within the material being cut.

Finally, it’s important to understand that all of these parameters must be carefully balanced in order to achieve optimal performance when cutting metal pipes with lasers. By carefully adjusting each parameter individually and then monitoring their combined effect on overall performance, it’s possible to optimize a setup for maximum efficiency and accuracy when performing metal pipe laser cutting operations.

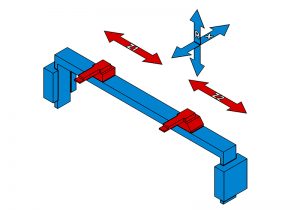

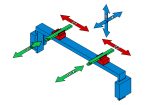

Evaluating Machine Features and Specifications for Metal Pipe Laser Cutting

When evaluating machine features and specifications for metal pipe laser cutting, there are several important considerations. The most important factor is the power of the laser. Laser cutting machines are typically rated in watts, with higher wattage lasers offering greater cutting capabilities. Additionally, the type of laser used will affect the cutting performance; CO2 lasers offer more versatility and better edge quality while fiber lasers provide faster cutting speeds and are better suited for thicker materials.

The size of the work area is also an important factor to consider when evaluating a metal pipe laser cutter. A larger work area allows for larger pipes to be cut, while a smaller work area limits the size of pipes that can be cut. It’s also important to consider the accuracy of the machine; some machines have higher accuracy ratings than others, which can be beneficial when precision cuts are required.

Other features to consider include software capabilities, such as CAD/CAM programs that allow users to create complex designs; speed settings that can be adjusted depending on material thickness and type; and safety features such as anti-collision sensors or enclosed cutting chambers. It’s also helpful to evaluate whether a machine offers automatic nozzle cleaning or offline programming capabilities so that operators don’t have to manually set up each job.

Finally, it’s important to look at the warranty and support offered by the manufacturer in case any problems arise with the machine during its lifetime. This will ensure that any potential issues can be addressed quickly and easily, minimizing downtime and maximizing efficiency.

By taking into account all these factors when evaluating metal pipe laser cutters, buyers can make sure they select a machine that meets their specific needs and provides reliable performance over time.

Investigating Safety Requirements for Metal Pipe Laser Cutting Machines

Investigating safety requirements for metal pipe laser cutting machines is a necessary step in ensuring the safety of workers and operators. Laser cutting is a highly efficient process that requires specialized equipment and technical expertise. The high intensity of the laser beam, coupled with the precision required for metal cutting, creates potential hazards to operators and other personnel in close proximity to the machine.

Therefore, it is important to understand and adhere to safety requirements when operating these machines. These requirements are designed to protect personnel from potential hazards such as exposure to laser radiation, burns, and electric shock. In addition, they also protect against other risks associated with operating metal pipe laser cutting machines such as fire or explosion due to flammable materials or improper ventilation.

To ensure compliance with safety requirements, manufacturers of metal pipe laser cutting machines provide detailed information on how their equipment should be operated safely. This includes information on how to properly secure the machine during operation and maintenance, proper ventilation requirements, and procedures for controlling access to the area where the machine is being operated.

Additionally, manufacturers also provide detailed instructions on proper safety gear that should be worn when operating these machines such as eye protection goggles, protective clothing (including flame retardant material), and respirators for filtering out fumes from laser cut materials. Operators must be adequately trained in the use of this equipment before being allowed to operate a metal pipe laser cutting machine.

Finally, it is important to inspect the metal pipe laser cutting machine prior to each use for any signs of damage or wear that could affect its performance or create potential hazards during operation. This includes inspecting electrical components for frayed wires or damaged insulation as well as checking moving parts for signs of wear or binding that could cause injury or impede performance during operation. Any necessary repairs should be performed by qualified personnel before using the machine again.

In summary, investigating safety requirements for metal pipe laser cutting machines is an important step in ensuring safe operation of this specialized equipment. Adhering to these safety protocols can help prevent serious injury or death due to exposure to hazardous conditions such as radiation exposure or fire hazards created by improper ventilation systems or faulty electrical components

Exploring Post-Processing Options for Metal Pipe Laser Cut Parts

Exploring post-processing options for metal pipe laser cut parts is an important step in the manufacturing process. Laser cutting is a fast and precise method of cutting metal, but it does require some additional steps to ensure that the parts are ready for use. Depending on the application, post-processing can range from simple cleaning to complex finishing operations such as machining and welding.

The most common post-processing option for laser cut metal pipe parts is cleaning. Cleaning removes debris from the surface of the part and helps ensure a smooth finish. This is typically done using compressed air or a vacuum cleaner, depending on the size of the part. If necessary, abrasive media such as sandpaper or steel wool can be used to remove any remaining residue or dirt.

In addition to cleaning, machining operations may be needed to improve dimensional accuracy and add features such as threads or holes. This can be done by hand with tools such as drills and taps or by CNC machining centers. CNC machines are particularly useful when working with complex geometries or multiple operations in one setup.

Welding is another common post-processing option for laser cut metal pipe parts. This can be used to join two pieces together, create complex shapes, or repair any damage caused during the cutting process. Laser welders are commonly used for this application due to their high precision and ability to produce strong welds without warping the material. However, manual welding may also be necessary depending on the application.

Finally, finishing operations may be needed to improve corrosion resistance or add aesthetic value to the part. These include processes such as anodizing, plating, painting, powder coating, and more depending on the application requirements. The choice of finishing will depend on factors such as cost and environmental considerations; however, it is important that these processes are carried out properly in order to ensure a quality finish that meets customer expectations.

Exploring post-processing options for laser cut metal pipe parts is essential in order to achieve a quality end product that meets customer specifications and requirements. The right combination of cleaning, machining, welding and finishing operations will ensure that each part meets its intended purpose while providing long lasting performance in its intended environment

Conclusion

The right metal pipe laser cutting machine can be a key factor in ensuring the success of any project. Taking the time to consider the size, power, and features of different machines can help to ensure that you select the best option for your needs. With this comprehensive guide to choosing the right metal pipe laser cutting machine, you can make an informed decision that will meet your project's demands and ensure optimal performance.