What is a 3 axis laser cutting machine?

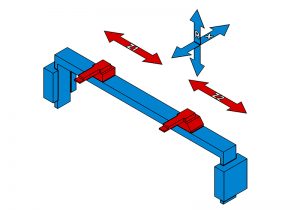

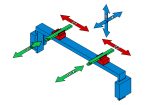

A 3 axis laser cutting machine is a type of industrial machine that uses a laser beam to cut materials, such as metal, plastic, or wood. It is called a "3 axis" machine because it is capable of moving the laser beam in three dimensions (X, Y, and Z).

The laser beam is directed through a series of mirrors and lenses, which focus the beam onto the material to be cut. The movement of the laser beam is controlled by computer numerical control (CNC) software, which allows the machine to cut precise shapes and patterns into the material.

3 axis laser cutting machines are commonly used in manufacturing, fabrication, and prototyping applications, where they are valued for their high precision and ability to produce complex shapes. They are also used in the aerospace, automotive, and medical device industries, among others.

What materials can be cut with a 3 axis laser cutter?

A 3 axis laser cutter can cut a wide range of materials, including:

- Metal: Most metals can be cut with a laser cutter, including steel, aluminum, brass, copper, and titanium.

- Plastic: Many types of plastic can be cut with a laser cutter, including acrylic, polycarbonate, and polystyrene.

- Wood: Laser cutters can be used to cut and engrave wood, although the depth of the cut may be limited.

- Fabric: Laser cutters can be used to cut and engrave fabric, such as cotton, silk, and leather.

- Paper and cardboard: Laser cutters can be used to cut and engrave paper and cardboard for applications such as prototyping, packaging, and printing.

- Glass: Laser cutters can be used to etch designs onto glass surfaces, although they are not capable of cutting through thick glass.

The materials that a laser cutter can cut will depend on the power of the laser and the specific properties of the material. Some materials may require the use of specialized laser cutting techniques or gases to facilitate the cutting process.

How accurate is a 3 axis laser cutter?

The accuracy of a 3 axis laser cutter is typically measured in microns, or thousandths of a millimeter. The precision of a 3 axis laser cutter depends on a number of factors, including the quality of the machine's optics and mirrors, the stability of the machine, and the skill of the operator.

In general, 3 axis laser cutters are capable of producing very accurate cuts, with tolerances as low as a few microns. However, the actual accuracy of a particular machine will depend on its specific design and operating conditions. It is important to carefully calibrate and maintain a 3 axis laser cutter to ensure that it is producing cuts to the desired level of precision.

What is the maximum thickness of material that can be cut with a 3 axis laser cutter?

The maximum thickness of material that can be cut with a 3 axis laser cutter depends on the power of the laser and the specific properties of the material. In general, the higher the laser power and the more absorbent the material, the thicker the material can be cut.

For example, a low-power laser cutter may be able to cut through a few millimeters of wood or plastic, while a high-power laser cutter may be able to cut through several centimeters of metal.

It is important to note that the maximum cutting thickness will also depend on the specific configuration of the laser cutter and the quality of the cut desired. For example, increasing the laser power or using a more focused beam may allow the cutter to cut through thicker material, but it may also result in a rougher or less precise cut.

How does the power of the laser affect the speed and quality of the cuts produced by a 3 axis laser cutter?

The power of the laser has a significant effect on the speed and quality of the cuts produced by a 3 axis laser cutter. In general, as the laser power increases, the cutter will be able to cut through thicker materials and will produce cuts with a cleaner edge. However, the trade-off is that higher laser power may also result in a slower cutting speed.

In addition, the focus of the laser beam can also affect the speed and quality of the cuts. A more focused beam will produce a smaller, more precise cut, but it may also cut more slowly than a less focused beam.

It is important to optimize the laser power and focus for the specific material and application to achieve the desired balance between speed and quality. This may involve adjusting the laser power and focus, as well as using specialized laser cutting techniques or gases to facilitate the cutting process.

Can a 3 axis laser cutter cut complex shapes or is it limited to straight lines and simple geometric shapes?

A 3 axis laser cutter is capable of cutting complex shapes, as well as straight lines and simple geometric shapes. The movement of the laser beam in the X, Y, and Z axes allows the cutter to produce a wide range of shapes and patterns.

The specific shapes that a 3 axis laser cutter can produce are limited only by the capabilities of the machine and the creativity of the operator. Many 3 axis laser cutters are equipped with CNC software, which allows the operator to input detailed designs and have the machine automatically produce the cuts.

In addition, some 3 axis laser cutters are equipped with additional axes of motion or other specialized features, such as a rotary axis for cutting cylindrical objects or a shuttle table for cutting large sheets of material. These features can further expand the range of shapes that a 3 axis laser cutter is capable of producing.

How does the choice of gas (e.g., oxygen, nitrogen) used during the cutting process affect the quality of the cuts produced by a 3 axis laser cutter?

The choice of gas used during the cutting process can affect the quality of the cuts produced by a 3 axis laser cutter in several ways.

Oxygen is often used as a cutting gas for non-metal materials, such as wood and plastic. When the laser beam hits the material, the oxygen reacts with the material, causing it to burn and creating a clean, precise cut. Oxygen can also help to remove any debris or slag that is produced during the cutting process.

Nitrogen, on the other hand, is commonly used as a cutting gas for metal materials. Nitrogen does not react with the material in the same way as oxygen, but it can help to prevent the material from oxidizing or discoloring during the cutting process. Nitrogen can also help to produce a smoother, more polished edge on the cut material.

In general, the choice of gas will depend on the specific material and application, as well as the desired quality of the cut. Some 3 axis laser cutters are equipped with multiple gas lines, which allows the operator to switch between different gases as needed.

What safety precautions should be taken when operating a 3 axis laser cutter?

Laser cutting can be a dangerous activity, as the laser beam is highly concentrated and can cause serious injury if it comes into contact with skin or eyes. It is important to take appropriate safety precautions when operating a 3 axis laser cutter to protect the operator and anyone else who may be in the vicinity of the machine.

Here are some general safety precautions to consider when operating a 3 axis laser cutter:

- Wear appropriate personal protective equipment, including safety glasses, gloves, and a lab coat.

- Follow the manufacturer's instructions for safe operation of the machine.

- Keep the work area clean and free of clutter to minimize the risk of accidents.

- Do not look directly into the laser beam or point the beam at anyone else.

- Keep a fire extinguisher or other fire suppression equipment nearby in case of accidents.

- Turn off the laser cutter and unplug it when it is not in use.

- Regularly inspect the machine and its components for signs of wear or damage, and repair or replace any damaged parts as necessary.

By following these safety precautions, you can help to ensure that the 3 axis laser cutter is used safely and efficiently.

How do you troubleshoot problems with a 3 axis laser cutter?

There are several steps you can take to troubleshoot problems with a 3 axis laser cutter:

- Check the machine's control panel for error messages or diagnostic codes, which can provide clues about the nature of the problem.

- Inspect the machine's optics and mirrors for signs of damage or contamination, which can cause the laser beam to be misaligned or weakened.

- Check the laser cutter's gas lines and nozzles for blockages or leaks, which can affect the quality of the cuts.

- Make sure that the material being cut is properly aligned with the laser beam and that it is secured in place to prevent movement during the cutting process.

- Check the condition of the machine's cutting bed and blade, as wear and damage can affect the quality of the cuts.

- Make sure that the machine's cooling system is functioning properly, as overheating can cause problems with the laser beam and other components.

- If the problem persists, consider consulting the machine's manual or contacting the manufacturer for additional guidance.

By following these steps, you can often identify and fix common problems with a 3 axis laser cutter. In some cases, more complex problems may require the assistance of a trained technician.

What is the maintenance required for a 3 axis laser cutter and how often should it be performed?

Proper maintenance is essential to ensure that a 3 axis laser cutter is operating safely and efficiently. The specific maintenance tasks and frequency will depend on the specific machine and the manufacturer's recommendations.

Here are some general maintenance tasks that may be required for a 3 axis laser cutter:

- Cleaning: The machine's optics, mirrors, and other components should be regularly cleaned to remove dust, debris, and other contaminants.

- Lubrication: The machine's moving parts, such as the cutting bed and blade, should be lubricated to prevent wear and ensure smooth operation.

- Inspection: The machine should be regularly inspected for signs of wear or damage, and any damaged parts should be repaired or replaced as necessary.

- Calibration: The machine's optics and other components should be calibrated to ensure that the laser beam is properly aligned and focused.

- System checks: The machine's software and hardware should be checked for updates and to ensure that they are functioning correctly.

It is important to follow the manufacturer's recommendations for maintenance tasks and frequency to ensure that the 3 axis laser cutter is operating at its best. In general, more frequent maintenance may be required for machines that are used heavily or in harsh environments, while less frequent maintenance may be sufficient for machines that are used less frequently.

How much does a 3 axis laser cutter cost and what factors influence the price?

The cost of a 3 axis laser cutter can vary significantly depending on a number of factors, including the size of the machine, the power of the laser, the precision of the cuts, and the materials that the machine is capable of cutting.

In general, 3 axis laser cutters range in price from a few thousand dollars for a small, low-power machine to several hundred thousand dollars for a large, high-power machine.

Other factors that can influence the price of a 3 axis laser cutter include the machine's features and capabilities, such as its cutting speed, the number of axes of motion, and the type of CNC software it uses.

The cost of ownership for a 3 axis laser cutter should also be considered, including the cost of maintenance, repairs, and consumables, such as laser tubes and cutting gases.

When shopping for a 3 axis laser cutter, it is important to carefully consider your specific needs and budget to find a machine that is a good fit for your application.