Introduction:

Ironworker hydraulic presses are essential machine tools in the metal fabrication industry, used for a variety of tasks such as cutting, punching, bending, and shearing metal. They are designed for heavy-duty use, making them ideal for demanding industrial applications. In this blog post, we will dive into the design, applications, and benefits of ironworker hydraulic presses, providing a comprehensive understanding of these versatile tools.

The purpose of this blog post is to educate metal fabrication professionals and enthusiasts about ironworker hydraulic presses, highlighting their design, applications, and benefits. By the end of this post, you will have a thorough understanding of why ironworker hydraulic presses are an essential tool in the metal fabrication industry and why they should be considered for your metal fabrication needs.

Design:

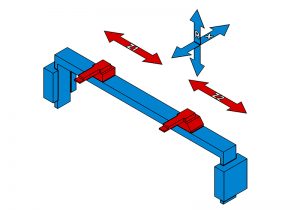

Ironworker hydraulic presses consist of a hydraulic pump, cylinder, and ram. The hydraulic pump generates the pressure needed to move the ram and perform the desired task, while the cylinder holds the ram in place. The ram carries out the cutting, punching, bending, or shearing action.

These presses are typically built with a robust, heavy-duty construction to ensure they can handle even the toughest fabrication tasks. The design of ironworker hydraulic presses is optimized for reliability and durability, ensuring that they can operate continuously for extended periods without maintenance or downtime. The robust construction and design of these presses make them ideal for heavy-duty industrial applications, where reliability and efficiency are of utmost importance.

Applications:

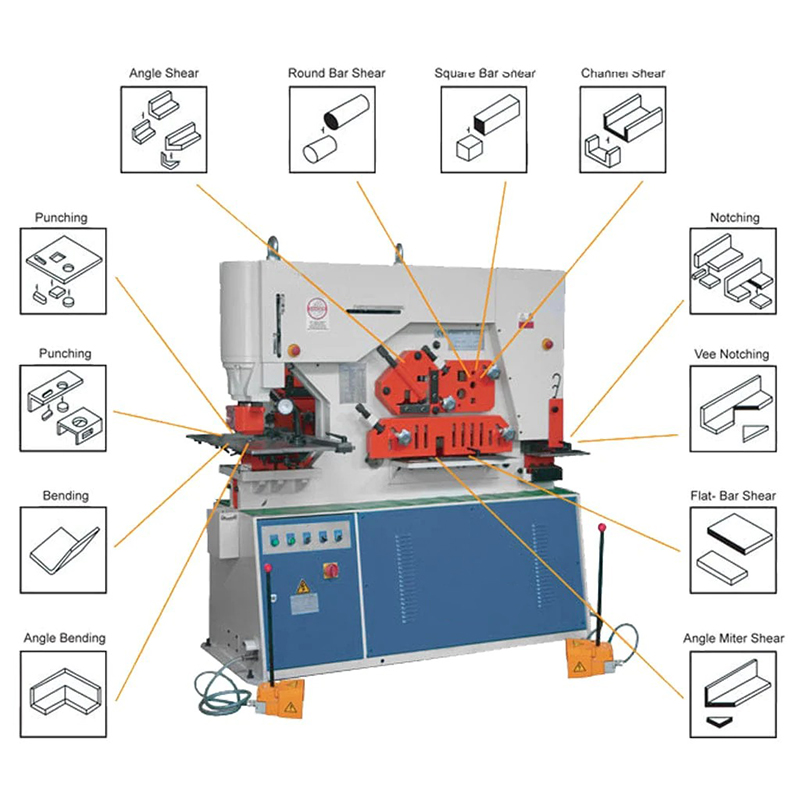

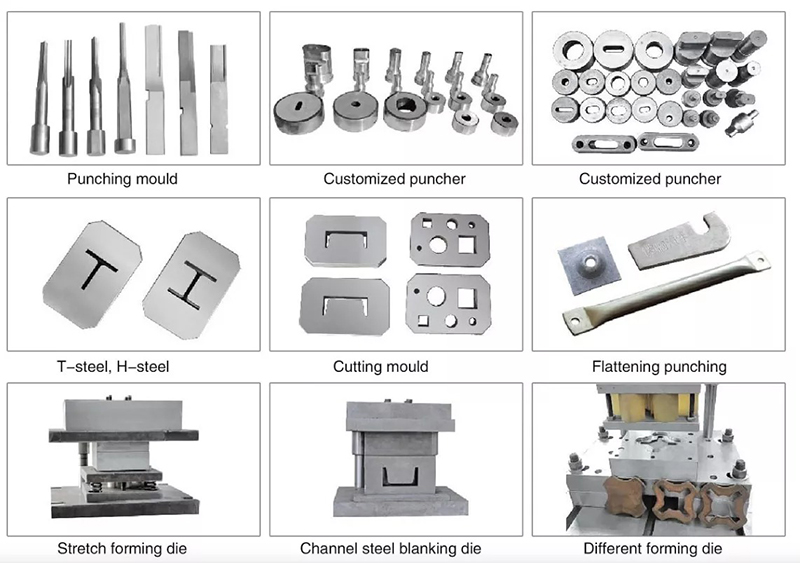

Ironworker hydraulic presses are used in a wide range of industrial applications, including construction, manufacturing, and metal fabrication. They are ideal for cutting and shaping large sheets of metal, as well as for creating intricate designs and shapes. In addition, ironworker hydraulic presses are often used for punching holes in metal sheets, for bending and forming metal into specific shapes, and for shearing metal into the desired length.

The versatility of ironworker hydraulic presses makes them suitable for a variety of metal fabrication tasks, and they are often used in both small and large scale metal fabrication operations. These presses are commonly found in metal fabrication shops, construction sites, and manufacturing facilities, where their versatility and heavy-duty construction make them an indispensable tool. Regardless of the task at hand, ironworker hydraulic presses provide a reliable and efficient solution for metal fabrication professionals.

Benefits:

Ironworker hydraulic presses offer several key benefits over traditional metal fabrication tools and methods. Firstly, they are incredibly versatile, allowing metal fabrication professionals to perform a variety of tasks with just one machine. This versatility saves time and money, as it eliminates the need for multiple tools and machines for different fabrication tasks.

In addition, ironworker hydraulic presses are more accurate and efficient than traditional metal fabrication tools, reducing the risk of errors and rework. They also provide greater control and precision, allowing for intricate designs and shapes to be created with ease.

The cost and time savings provided by ironworker hydraulic presses are substantial, and their heavy-duty construction ensures that they can handle even the toughest fabrication tasks. Whether you are working on a small or large scale project, ironworker hydraulic presses provide a reliable and efficient solution for metal fabrication professionals.

Finally, ironworker hydraulic presses are well suited for heavy-duty work, making them ideal for demanding industrial applications. Their robust construction and design ensure that they can operate continuously for extended periods without maintenance or downtime, providing reliable and efficient results every time.

Conclusion:

In conclusion, ironworker hydraulic presses are an essential tool for metal fabrication professionals, offering versatility, efficiency, accuracy, and heavy-duty construction. Whether you are in construction, manufacturing, or metal fabrication, these presses provide a reliable and efficient solution for a wide range of tasks.

In this blog post, we have explored the design, applications, and benefits of ironworker hydraulic presses, providing a comprehensive understanding of these versatile machine tools. From the heavy-duty construction to the cost and time savings, ironworker hydraulic presses offer numerous advantages over traditional metal fabrication tools and methods.

In closing, we highly recommend ironworker hydraulic presses for those in need of a versatile machine tool for metal fabrication. With their robust construction, efficiency, accuracy, and versatility, they provide a reliable solution for even the toughest fabrication tasks. So, if you are looking for a reliable and efficient tool for your metal fabrication needs, consider investing in an ironworker hydraulic press.