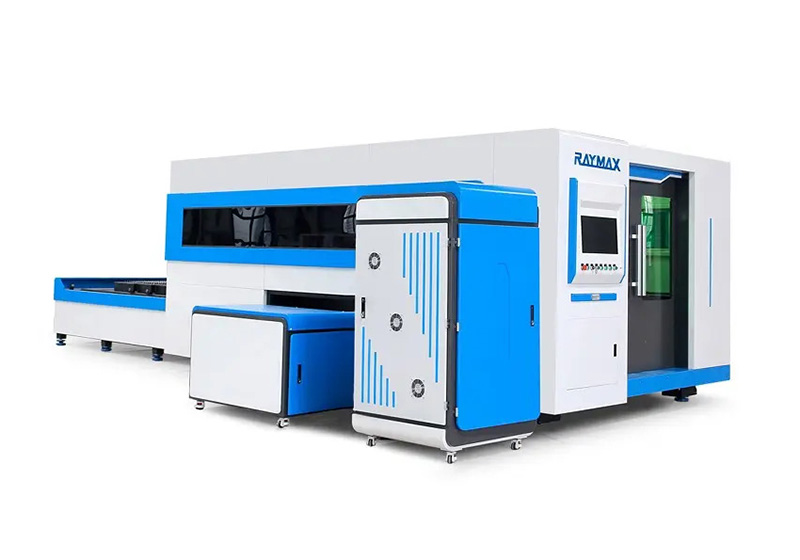

The manufacturing industry has seen a surge in technological advancement over past few years, and one the most important pieces of is the 2kw fiber laser cutting machine. This type of machine can help optimize production processes by providing faster, more accurate, and more efficient cutting. It also offers a range of benefits such as increased safety, reduced material waste, improved production quality, and improved environmental sustainability. This article will discuss the various ways in which a 2kw fiber laser cutting machine can be used to optimize manufacturing processes and provide an overview of its various features.

Benefits of Using 2kw Fiber Laser Cutting Machines for Optimizing Manufacturing Processes

The 2kw fiber laser cutting machine is a powerful tool for optimizing manufacturing processes. This machine has several benefits that make it an ideal choice for industrial applications. The high-powered 2kw fiber laser cutting machine offers superior performance compared to other traditional methods of manufacturing. This makes it an ideal choice for many industrial processes, from metal cutting and engraving to welding and heat treating.

The 2kw fiber laser cutting machine is highly efficient, using only a fraction of the energy consumed by traditional methods. This means lower energy costs and improved efficiency in production. Additionally, the machine is capable of producing high-precision cuts at higher speeds than traditional methods. This allows for faster production times and increased accuracy in the finished product.

The use of the 2kw fiber laser cutting machine also reduces waste material, as it requires less material than traditional methods to complete a job. This reduces overall material costs while increasing productivity. Furthermore, because this type of cutting uses lasers instead of mechanical force, there is less risk of physical damage to the material being cut or engraved. This makes it safer to use around sensitive materials such as electronics and medical devices.

The 2kw fiber laser cutting machine also offers greater versatility than other methods, as it can cut multiple materials at once with ease and precision. The machine is capable of processing a wide range of materials including metal alloys, plastics, wood, leathers, ceramics and more with exceptional accuracy and speed. Additionally, this type of cutting does not require any specialized tools or preparation before use which can save time in the production process.

Overall, the 2kw fiber laser cutting machines provide superior performance compared to other traditional methods when it comes to optimizing manufacturing processes in various industries such as automotive manufacturing, electronics production and aerospace engineering among others. Its energy efficiency makes it cost-effective while its versatility allows for faster production times with higher precision than ever before possible with traditional methods. The machine is also safe to use around sensitive materials due to its non-contact approach and reduced risk of physical damage during operation which makes it a great choice for many industrial applications requiring precision cuts at high speeds with minimal waste material produced along the way

Advantages of 2kw Fiber Laser Cutting Machines Over Traditional Methods

2kw Fiber Laser Cutting Machines offer a range of advantages over traditional cutting methods, making them the ideal choice for a variety of applications. These machines offer increased speed and accuracy, reduced labor costs, and improved safety.

The primary advantage of 2kw Fiber Laser Cutting Machines is the speed at which they can cut through material. The laser beam used in these machines can reach speeds of up to 200 meters per second, which is significantly faster than traditional cutting methods. This increased speed translates into shorter cycle times, which can reduce production costs and increase efficiency. Additionally, the laser beam can cut through a variety of materials with precision and accuracy that is not possible with other cutting methods.

The cost savings associated with 2kw Fiber Laser Cutting Machines are also significant. Because the machines are so efficient, they require less labor to operate than traditional cutting methods. This reduces labor costs and allows businesses to devote more resources to other areas of their operations. Additionally, these machines use less energy than other cutting methods, resulting in lower energy bills.

Finally, 2kw Fiber Laser Cutting Machines provide improved safety compared to other cutting methods. The laser beam used in these machines does not generate any hazardous fumes or dust particles that could be inhaled by workers in the area. This makes them ideal for applications where worker safety is a priority. Additionally, the laser beam does not generate any heat or sparks that could cause fires or explosions if mishandled or used improperly.

In conclusion, 2kw Fiber Laser Cutting Machines offer many advantages over traditional cutting methods due to their increased speed and accuracy, reduced labor costs, and improved safety features. These machines are ideal for businesses looking to improve their efficiency while maintaining high standards of worker safety.

How to Improve Efficiency in Manufacturing Processes Through 2kw Fiber Laser Cutting Machines

2kw fiber laser cutting machines are essential for manufacturing processes. They provide manufacturers with the precision and speed needed to produce quality products in a timely manner. As technology advances, manufacturers have access to even more advanced fiber laser cutting machines, allowing them to achieve greater efficiency in their manufacturing processes.

The 2kw fiber laser cutting machine is one of the most efficient machines on the market today. It utilizes a high-power laser beam that is focused on a thin sheet of metal, allowing it to be cut with extreme accuracy and speed. This machine is able to cut through a variety of materials including steel, aluminum, copper, brass, and titanium with ease. With its ability to cut through thick materials quickly and accurately, this machine increases the overall efficiency of any manufacturing process.

The 2kw fiber laser cutting machine also offers several features that improve the efficiency of the production process. For example, it has an automatic feed system that ensures precise cuts are made every time and eliminates manual handling of material which can lead to delays or mistakes. Additionally, this machine has an integrated software system which helps streamline production operations by automating certain tasks such as programming and data entry. This reduces time spent on tedious tasks and frees up staff for other tasks that require more attention.

This machine also offers several safety features which help protect both operators and materials from damage during operation. The protective enclosure helps reduce risk of injury by limiting exposure to high-powered lasers while the built-in fire suppression system helps ensure any sparks generated during cutting do not spread and cause fires or explosions.

Overall, the 2kw fiber laser cutting machine is an invaluable tool for any manufacturer looking to increase their efficiency in their production processes. It provides accuracy and speed along with several additional features which help streamline operations while providing maximum safety for operators and materials alike.

Automating the Manufacturing Process with 2kw Fiber Laser Cutting Machines

The manufacturing industry has been revolutionized by the introduction of 2kw fiber laser cutting machines. These machines offer an efficient, cost-effective way to cut various materials with precision and accuracy. Laser cutting technology offers an automated solution to the traditional methods of manufacturing, such as sawing, drilling and milling.

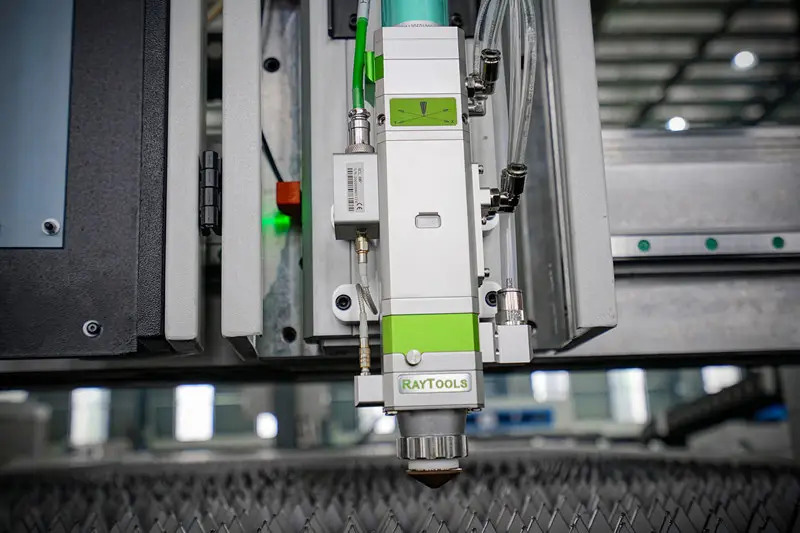

The 2kw fiber laser cutting machines are capable of handling a variety of materials, such as stainless steel, aluminum, brass, copper and plastic. The laser beam is directed by a computer-controlled system that can easily be programmed to make precise cuts in a variety of shapes and sizes. This ensures that each part produced is consistent in quality and accuracy. The laser beam is able to cut through even the thickest materials with speed and accuracy while maintaining minimal heat input into the material being cut.

The automation of the manufacturing process with 2kw fiber laser cutting machines also allows for faster production times while reducing labor costs. The computer-controlled system can be programmed to quickly move from one part to another without manual intervention or re-adjustment of settings. This allows for a more efficient production process as well as fewer errors in the finished product. Additionally, because the laser beam is so precise it can be used to create intricate designs on metal surfaces that would not be possible with other methods of manufacturing.

In addition to providing greater efficiency and accuracy in production processes, 2kw fiber laser cutting machines are also environmentally friendly as they require less energy than other types of industrial machinery used for similar applications. They produce no hazardous waste or emissions during operation which makes them an ideal choice for businesses that want to reduce their environmental footprint while still meeting their production goals.

Overall, 2kw fiber laser cutting machines offer a reliable automated solution for manufacturers looking for increased efficiency and precision in their production processes while reducing labor costs and environmental impacts associated with traditional manufacturing techniques. With their ability to quickly cut through even the thickest materials with precision and speed they are quickly becoming an essential tool in many industrial settings today.

Ensuring Quality Output with 2kw Fiber Laser Cutting Machines

Ensuring quality output with 2kw fiber laser cutting machines is essential for any business that wants to remain competitive. This type of machine uses a high-powered laser beam to cut through metal with extreme precision and accuracy. The use of this type of equipment offers many advantages, including increased efficiency, improved quality, and cost savings.

When looking for a 2kw fiber laser cutting machine, it is important to consider the overall quality and performance of the equipment. This includes factors such as beam power, wavelength stability, speed, accuracy, and safety features. All these features must be taken into account when making an investment in this type of machine.

In terms of beam power, a 2kw fiber laser cutting machine can produce up to two kilowatts of power. This means that it can easily cut through thick materials such as aluminum or stainless steel without any issues. The wavelength stability ensures that the beam stays consistent throughout the entire cutting process. This eliminates inconsistencies in the final product and ensures a smooth finish on the edges of the material being cut.

Speed is also an important factor when it comes to ensuring quality output with a 2kw fiber laser cutting machine. These machines are able to cut through materials quickly and accurately while producing minimal waste material. This allows businesses to reduce their production time while still maintaining high levels of accuracy in their products.

Accuracy is essential for producing high-quality products with this type of equipment. The use of a powerful optical system allows these machines to accurately cut through metal at extremely precise angles without compromising on accuracy or safety features. Additionally, they are able to produce intricate designs with ease due to their advanced computerized control systems which can be programmed to follow complex patterns and shapes precisely.

Finally, safety features should not be overlooked when looking for a 2kw fiber laser cutting machine for your business needs. These machines are equipped with built-in safety mechanisms which help prevent accidents from occurring due to operator error or mechanical failure during operation. Additionally, they are designed with enclosed housings which protect against dust and other particles from entering the interior components during operation and help keep operators safe from harm while working near them.

By taking all these factors into consideration when purchasing a 2kw fiber laser cutting machine for your business needs you can ensure quality output at all times while also minimizing downtime due to maintenance requirements or operator errors during operation

Techniques for Enhancing Productivity with 2kw Fiber Laser Cutting Machines

2kw Fiber Laser Cutting Machines are highly advanced tools that provide businesses with the power to create complex and intricate designs with maximum efficiency. The machines are used in many industries including automotive, aerospace, and construction. With their cutting-edge technology, they enable companies to increase their production speed and accuracy while reducing costs.

The 2kw Fiber Laser Cutting Machines utilize a high-powered laser beam that is able to cut through a wide range of materials with ease. The laser beam is generated by a CO2 or fiber laser source which is then directed onto the material being cut by a system of mirrors and lenses. The speed at which the laser beam moves along the material is determined by the power of the laser source as well as the optics used in the cutting system. This enables businesses to cut intricate shapes into materials quickly and accurately without compromising on quality or safety.

To enhance productivity with these machines, it is important to use proper setup procedures for each job. This includes ensuring that all components are securely attached and properly aligned before beginning any cutting operation. Additionally, using an efficient cutting strategy can help optimize performance and reduce cycle times. Businesses should also pay close attention to their choice of materials as some materials may require more powerful lasers or additional setup steps in order to produce satisfactory results.

Furthermore, regular maintenance and calibration should be performed on these machines to ensure they remain in optimal working condition. This can include replacing worn parts, adjusting settings, and cleaning lenses or other components that may have accumulated dirt or dust over time. Regular maintenance will also help reduce downtime caused by equipment malfunctions or other issues that can arise due to improper use or setup procedures.

Finally, businesses should take advantage of the latest technological advancements available for these machines such as automated loading systems and software programs that can be used to streamline operations and reduce manual labor requirements associated with production processes. By utilizing these tools along with proper setup procedures, businesses can significantly improve productivity when using 2kw Fiber Laser Cutting Machines without sacrificing quality or safety standards.

Conclusion

Optimizing manufacturing processes with 2kw fiber laser cutting machines can be an effective solution for improving production efficiency and product quality. The advanced technology of the laser cutting machine offers a wide range of benefits, including high speed and accuracy, improved edge quality, and lower operational costs. Additionally, the machine is easy to use and maintain, making it ideal for any size manufacturing facility. By investing in a 2kw fiber laser cutting machine, companies can improve their production processes and ensure that their products are of the highest quality.