Introduction

Explanation of Double Action Press Machines

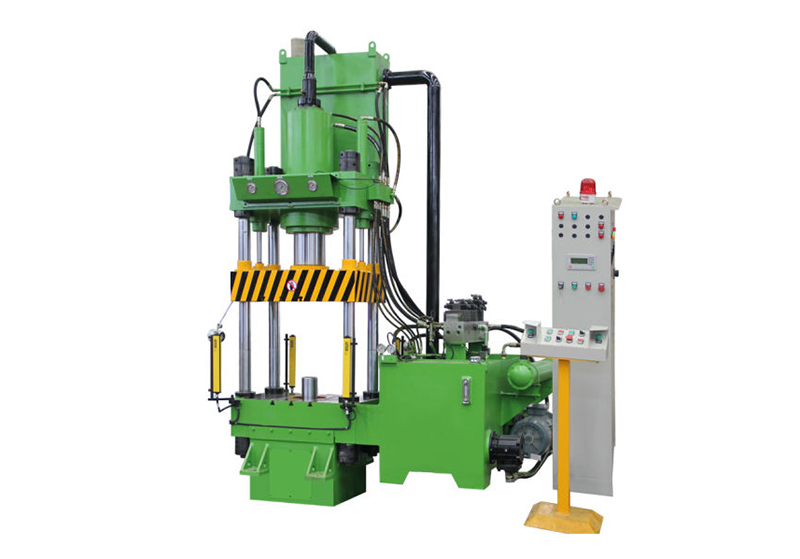

Double action press machines are specialized tools that are used to produce high precision parts with demanding dimensional tolerances. These machines are used in a variety of industries, including metal fabrication, automotive manufacturing, aerospace manufacturing, and consumer goods manufacturing, among others.

Importance of Understanding Double Action Press Machines

Double action press machines are complex tools that require a deep understanding of their design, construction, and working principles to operate effectively. A comprehensive understanding of these machines is essential for manufacturing engineers, maintenance technicians, and operators, who must work with them on a daily basis.

Purpose of the Blog Post

The purpose of this blog post is to provide a comprehensive guide to understanding double action press machines. The post will cover everything from the design and construction of these machines to their working principles, applications, benefits, and potential drawbacks. This information will help industry professionals make informed decisions about the use of double action press machines in their operations.

Design and Construction of Double Action Press Machines

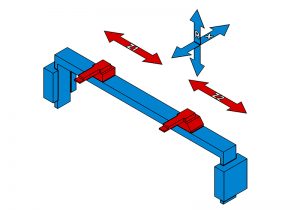

Explanation of Double Action Press Mechanism

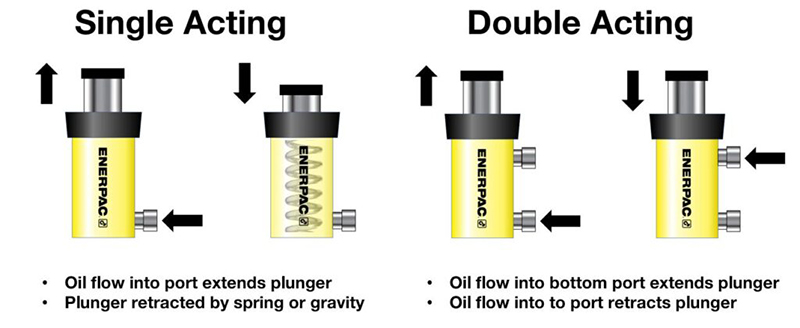

Double action press machines use a unique mechanism to produce high precision parts. The mechanism is based on the principles of hydraulic power and mechanical leverage, and involves the use of a plunger that moves in two directions, creating a double action stroke.

Materials Used in Construction

Double action press machines are typically constructed from high strength materials, such as steel, aluminum, and cast iron. These materials are chosen for their durability, strength, and resistance to wear and tear, which are critical factors in the production of high precision parts.

Key Components and Their Functions

Double action press machines are comprised of several key components, including the frame, platen, plunger, hydraulic system, and control system. The frame provides the structural support for the machine, while the platen holds the workpiece in place during the pressing operation. The plunger is the key component that generates the force required to produce the part. The hydraulic system provides the power required to move the plunger, and the control system manages the operation of the machine.

Design Considerations for Double Action Press Machines

In order to produce high precision parts, double action press machines must be designed with several critical factors in mind, including load capacity, stroke length, and precision of motion. These factors must be balanced against the size and cost of the machine, and the desired production rate. Other important design considerations include safety features, energy efficiency, and ease of maintenance.

Working Principles of Double Action Press Machines

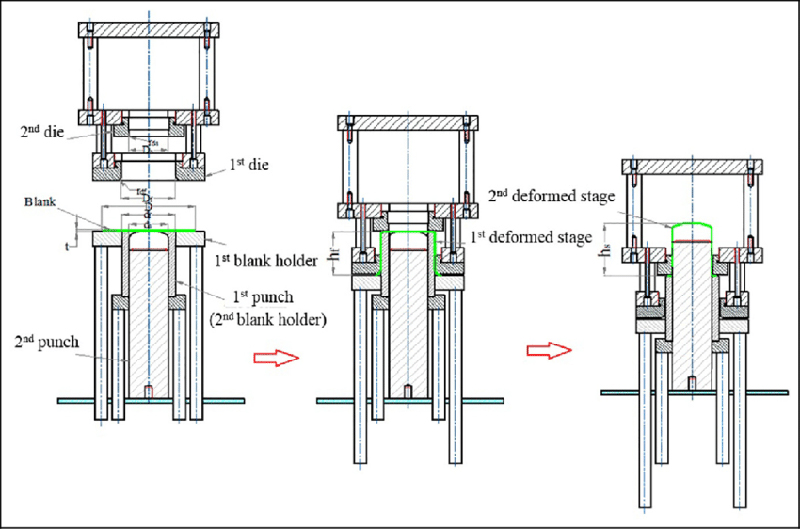

Explanation of the Stroke Cycle

The working principles of double action press machines are based on the stroke cycle of the plunger. During each stroke, the plunger moves in two directions, compressing and decompressing the hydraulic fluid to produce the required force. This double action mechanism allows the machine to produce a high level of precision and control, making it ideal for the production of high quality parts.

How the Machine Produces Force

Double action press machines produce force by using hydraulic power to move the plunger. The plunger is connected to the hydraulic system, which uses a pump to pressurize the fluid and create the force required to produce the part. The plunger is then controlled by the machine's control system, which manages the movement of the plunger and the timing of the stroke cycle.

Explanation of the Double Action Mechanism

The double action mechanism is what sets double action press machines apart from other types of press machines. The mechanism involves the use of a plunger that moves in two directions, creating a double action stroke. This mechanism allows the machine to produce a high level of precision and control, making it ideal for the production of high quality parts.

Role of Hydraulics in Double Action Press Machines

Hydraulics play a critical role in the operation of double action press machines. The hydraulic system provides the power required to move the plunger, and the fluid is carefully controlled by the machine's control system to ensure that the correct amount of force is applied to the workpiece. The use of hydraulic power also allows for the safe and efficient transfer of large amounts of force, making it possible to produce high precision parts with demanding dimensional tolerances.

Applications of Double Action Press Machines

Metal Fabrication

Double action press machines are commonly used in metal fabrication to produce high precision parts, such as stamped metal components, fasteners, and other small metal parts. The machines' ability to produce parts with demanding dimensional tolerances and consistent quality makes them ideal for metal fabrication operations.

Automotive Manufacturing

Double action press machines are also used in the automotive industry, where they are used to produce a variety of parts, including engine components, suspension parts, and body panels. The machines' high level of precision and control make them ideal for producing parts with demanding dimensional tolerances, such as tight tolerance engine components.

Aerospace Manufacturing

Double action press machines are used in the aerospace industry to produce high precision parts, such as fuselage panels, wing components, and other aerostructural parts. The machines' ability to produce parts with demanding dimensional tolerances and consistent quality makes them ideal for aerospace manufacturing operations.

Consumer Goods Manufacturing

Double action press machines are also used in the consumer goods industry, where they are used to produce a variety of parts, such as small metal parts for household appliances, electronics, and other consumer goods. The machines' high level of precision and control make them ideal for producing parts with demanding dimensional tolerances, such as small metal parts with tight dimensional tolerances.

Other Applications

Double action press machines are used in a variety of other industries, including medical device manufacturing, firearms manufacturing, and jewelry manufacturing, among others. The machines' ability to produce high precision parts with demanding dimensional tolerances makes them ideal for a wide range of manufacturing operations.

Benefits of Using Double Action Press Machines

High Precision

One of the key benefits of using double action press machines is the high level of precision they offer. The machines' double action mechanism and hydraulic power allow them to produce parts with tight dimensional tolerances and consistent quality, making them ideal for producing high precision parts.

High Control

Another benefit of double action press machines is the high level of control they offer. The machines' control systems manage the movement of the plunger and the timing of the stroke cycle, allowing for precise control over the force applied to the workpiece. This high level of control makes it possible to produce parts with demanding dimensional tolerances and consistent quality.

Efficient Production

Double action press machines are also known for their efficiency in producing high precision parts. The machines' use of hydraulic power allows for the safe and efficient transfer of large amounts of force, making it possible to produce high precision parts quickly and efficiently.

Versatility

Double action press machines are versatile machines, capable of producing a wide range of high precision parts for a variety of industries. The machines' ability to produce parts with tight dimensional tolerances and consistent quality make them ideal for a wide range of manufacturing operations.

Increased Productivity

The efficiency and versatility of double action press machines can lead to increased productivity in manufacturing operations. The machines' ability to produce high precision parts quickly and efficiently can help to increase production rates, reduce lead times, and improve overall production efficiency.

Potential Drawbacks of Double Action Press Machines

High Cost

Double action press machines are known for their high level of precision and control, but this comes at a cost. The machines are typically more expensive than other types of metal fabrication equipment, making them less accessible for small or budget-conscious operations.

Complex Operation

Another potential drawback of double action press machines is their complexity of operation. The machines' double action mechanism and hydraulic power require a higher level of technical expertise to operate and maintain compared to other types of metal fabrication equipment.

Limited Material Capabilities

Double action press machines are typically limited in the types of materials they can process. The machines are best suited for processing metal, and may not be suitable for processing other materials, such as plastics or composites.

High Maintenance Costs

Double action press machines are known for their high level of precision and control, but this also means they require a higher level of maintenance compared to other types of metal fabrication equipment. The machines' complex mechanism and hydraulic power system require regular maintenance to ensure optimal performance, which can add to the overall cost of ownership.

Space Requirements

Double action press machines are also known for their large size and heavy weight, making them more challenging to integrate into existing manufacturing operations. The machines' large size can also make them difficult to transport or move to different locations.

Conclusion

Double action press machines are versatile and efficient machines that offer high precision and control for producing high precision metal parts. Despite their high cost, complex operation, and limited material capabilities, the machines' ability to produce high precision parts quickly and efficiently can make them a valuable investment for manufacturing operations. The high level of precision and control offered by double action press machines can lead to increased productivity, reduced lead times, and improved overall production efficiency.

In conclusion, double action press machines are a valuable investment for manufacturing operations looking to produce high precision metal parts with demanding dimensional tolerances. While there are potential drawbacks to using these machines, such as high cost, complex operation, and limited material capabilities, the benefits of increased productivity, improved production efficiency, and the ability to produce high precision parts make double action press machines a valuable investment for many manufacturing operations.