What is a 5 axis press brake and how does it differ from other types of press brakes?

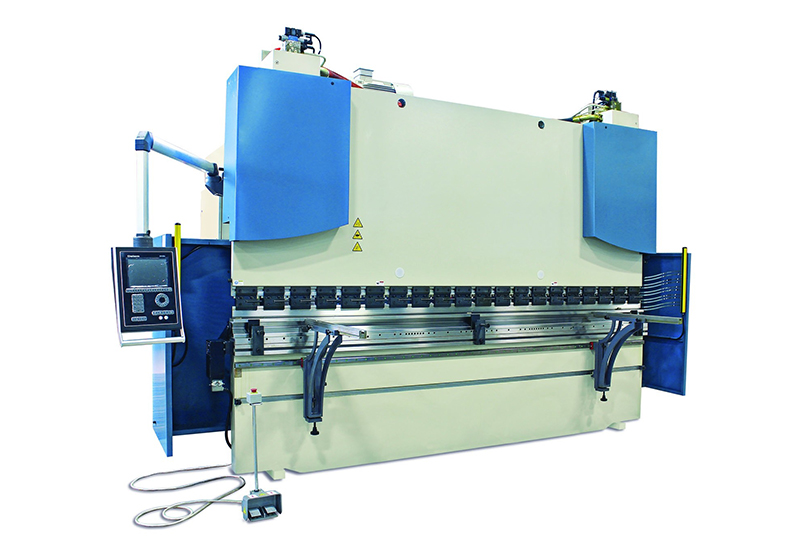

A press brake is a machine tool that is used to bend sheet and plate metal. It consists of a bed or ram that holds the upper tooling, called the punch, and a lower tooling, called the die, which is mounted on a V-shaped or horizontal bed. Press brakes are used to create bends in sheet metal by pressing the punch against the die with a specified force.

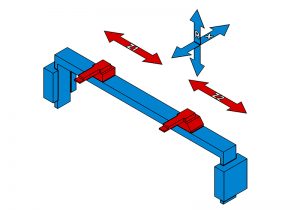

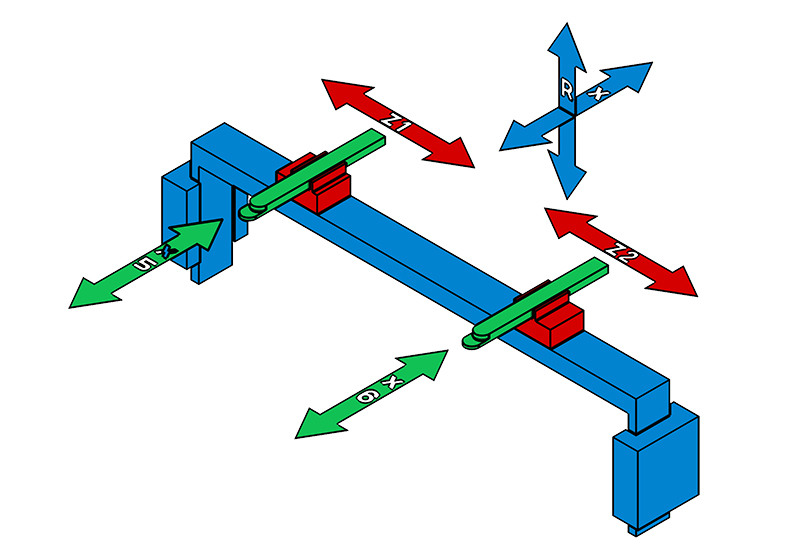

A 5 axis press brake is a type of press brake that has an additional two axes of motion beyond the standard X, Y, and Z axes that are found on traditional press brakes. These additional axes allow the punch and die to move in a more complex, three-dimensional path, which makes it possible to form parts with a wider range of shapes and geometries. Some 5 axis press brakes also have a fourth axis of motion that rotates the punch and die around the Y axis, which further expands the range of shapes that can be formed.

One of the main differences between a 5 axis press brake and other types of press brakes is the level of precision and complexity that it can achieve. The additional axes of motion allow for more precise control over the shape and position of the formed parts, which can be important in applications where tight tolerances are required. However, the added complexity of the machine can also make it more expensive to purchase and maintain, and it may require more advanced programming and setup procedures.

What are the advantages and disadvantages of using a 5 axis press brake?

Here are some of the advantages of using a 5 axis press brake:

- Greater precision: The additional axes of motion allow for more precise control over the shape and position of the formed parts, which can be important in applications where tight tolerances are required.

- Greater versatility: The expanded range of motion offered by a 5 axis press brake allows it to form a wider range of shapes and geometries than a traditional press brake. This can be useful in applications where multiple different part types are being produced.

- Increased productivity: Depending on the specific application, it may be possible to produce parts more quickly on a 5 axis press brake due to the increased versatility and precision of the machine.

Some potential disadvantages of using a 5 axis press brake include:

- Higher cost: 5 axis press brakes tend to be more expensive to purchase and maintain than traditional press brakes, due to the added complexity of the machine.

- Increased setup time: The additional axes of motion and the need for more advanced programming may require more time to set up the machine for production.

- Greater operator skill level required: Operating a 5 axis press brake typically requires a higher level of skill and training than a traditional press brake, as the machine is more complex and requires more advanced programming and setup procedures.

- Limited compatibility with certain tooling: Some types of tooling, such as certain styles of dies, may not be compatible with a 5 axis press brake due to the additional axes of motion.

What types of materials can be formed using a 5 axis press brake?

A 5 axis press brake can be used to form a wide range of materials, including various types of sheet and plate metal, such as mild steel, aluminum, brass, copper, and stainless steel. The specific materials that can be formed will depend on the capabilities of the machine, including the size and tonnage of the press brake, as well as the properties of the material being formed. Some materials, such as high-strength steels or hard metals, may require a press brake with higher tonnage or special tooling to form them properly.

It's important to note that the thickness and type of material being formed can have a significant impact on the performance of the press brake and the quality of the formed parts. Materials with a higher strength-to-weight ratio or that are harder or more brittle may be more challenging to form and may require special techniques or tooling. In general, it's best to consult with the manufacturer of the press brake or a knowledgeable specialist to determine the appropriate material and processing parameters for a particular application.

How does the setup and programming of a 5 axis press brake compare to a traditional press brake?

The setup and programming of a 5 axis press brake can be more complex than a traditional press brake due to the additional axes of motion and the need for more advanced programming to control them. In general, the setup and programming process for a 5 axis press brake may involve the following steps:

Select and install the appropriate tooling:

This will typically involve selecting and installing the punch and die that are required to form the desired part geometry. Depending on the complexity of the part, it may also be necessary to install additional tooling, such as special dies or forming tools.

Set up the machine:

This will typically involve positioning the machine and tooling according to the requirements of the part being formed. This may involve adjusting the position of the punch and die, as well as any additional tooling that is being used.

Program the machine:

This will typically involve creating a program that specifies the sequence of operations that the machine will perform to form the desired part. This may involve specifying the positions and movements of the punch and die, as well as any additional tooling that is being used. Some 5 axis press brakes may also require the input of additional parameters, such as the tonnage or force that will be applied during the forming process.

Overall, the setup and programming of a 5 axis press brake tends to be more time-consuming and require a higher level of skill and training compared to a traditional press brake. However, the increased precision and versatility of a 5 axis press brake may justify the additional effort required to set it up and program it for certain applications.

What safety considerations should be taken into account when operating a 5 axis press brake?

There are several important safety considerations to keep in mind when operating a 5 axis press brake:

- Wear appropriate personal protective equipment (PPE): This may include items such as safety glasses, earplugs, gloves, and steel-toed boots.

- Keep the work area clean and free of clutter: A cluttered work area can increase the risk of accidents or injuries.

- Follow all machine operating procedures: Make sure to follow all procedures and guidelines for operating the press brake, including any relevant safety procedures.

- Use the machine in accordance with its rated capacity: Do not exceed the maximum tonnage or force that the machine is designed to handle.

- Use caution when working with the punch and die: The punch and die can be sharp and can cause injuries if handled improperly.

- Use caution when working with sheet metal: Sheet metal can be sharp and can cause cuts or punctures if handled improperly.

- Use caution when working with hazardous materials: If you are working with materials that are hazardous or potentially toxic, make sure to follow all relevant safety procedures to protect yourself and others.

- Keep your hands and other body parts away from the forming area: The press brake uses a lot of force and can cause serious injuries if you get your hands or other body parts caught in the forming area.

By following these safety guidelines and using caution when operating the press brake, you can help to reduce the risk of accidents or injuries.

How do you maintain and troubleshoot a 5 axis press brake?

Proper maintenance and troubleshooting of a 5 axis press brake can help to ensure that the machine is running smoothly and efficiently, and can also help to extend its lifespan. Here are some general guidelines for maintaining and troubleshooting a 5 axis press brake:

- Follow the manufacturer's maintenance recommendations: The manufacturer of the press brake will typically provide guidelines for how to maintain the machine, including recommendations for things like lubrication, cleaning, and replacing wear parts.

- Keep the machine clean: Regularly cleaning the press brake, including the punch and die, can help to prevent problems from occurring.

- Lubricate the machine according to the manufacturer's recommendations: Proper lubrication of the moving parts of the press brake can help to reduce wear and extend the life of the machine.

- Replace wear parts as needed: Parts such as the punch and die can wear out over time and may need to be replaced in order to maintain the performance of the press brake.

- Check and tighten all bolts and screws regularly: Loose bolts or screws can cause problems with the operation of the press brake, so it's important to check and tighten them regularly.

- Use a load cell: Using a load cell can help to identify problems with the machine's tonnage or force output.

- Keep accurate maintenance records: Keeping records of maintenance activities and any problems that arise can help to identify trends and potential issues before they become major problems.

By following these guidelines and addressing any problems as they arise, you can help to keep your 5 axis press brake running smoothly and efficiently. If you are having trouble troubleshooting a problem with the machine, it may be helpful to consult with the manufacturer or a trained service technician for assistance.

What are the typical production rates that can be achieved with a 5 axis press brake?

The production rate that can be achieved with a 5 axis press brake will depend on a number of factors, including the complexity and size of the parts being formed, the capabilities of the press brake, and the efficiency of the production process. Some 5 axis press brakes are designed for high-volume production and can achieve production rates of hundreds or even thousands of parts per hour, while others are more suited for low-volume or prototyping applications and may have lower production rates.

In general, the production rate of a 5 axis press brake will be influenced by factors such as:

- The size and complexity of the parts being formed: Smaller, simpler parts may be able to be produced more quickly than larger, more complex parts.

- The capabilities of the press brake: The size and tonnage of the press brake, as well as the speed and accuracy of the machine's movements, will all affect the production rate.

- The efficiency of the production process: Factors such as the time required for setup and changeover, the speed and accuracy of the programming, and the efficiency of the operator can all influence the overall production rate of the press brake.

Ultimately, the production rate that can be achieved with a 5 axis press brake will depend on the specific requirements of the application and the capabilities of the machine. It may be helpful to consult with the manufacturer or a knowledgeable specialist to determine the appropriate production rate for a particular application.

What is the lifespan of a 5 axis press brake and how can it be extended?

The lifespan of a 5 axis press brake can vary widely depending on a number of factors, including the quality of the machine, the conditions under which it is used, and the level of maintenance that it receives. In general, higher-quality press brakes that are well-maintained and used under appropriate conditions will have a longer lifespan than lower-quality machines that are poorly maintained and used in harsh conditions.

Here are some general tips for extending the lifespan of a 5 axis press brake:

- Follow the manufacturer's recommendations for maintenance: Regularly performing maintenance on the press brake, including tasks such as lubrication and cleaning, can help to extend the life of the machine.

- Use the machine within its rated capacity: Do not exceed the maximum tonnage or force that the machine is designed to handle, as this can cause excessive wear and damage to the machine.

- Use appropriate tooling: Using the correct tooling for the material and application can help to reduce wear and extend the life of the press brake.

- Protect the machine from harsh conditions: If possible, try to keep the press brake in a clean, dry environment, and protect it from extreme temperatures or other harsh conditions that could cause damage to the machine.

- Repair problems as soon as they arise: If you notice a problem with the press brake, it's important to address it as soon as possible in order to prevent the problem from worsening and potentially causing more serious damage.

By following these tips and performing regular maintenance on the press brake, you can help to extend its lifespan and ensure that it continues to operate smoothly and efficiently.

What are the different size and tonnage options available for 5 axis press brakes?

5 axis press brakes are available in a range of sizes and tonnage ratings to suit different applications. The size of the press brake is typically determined by the length of the bed or ram, which determines the maximum length of the parts that can be formed. Common bed lengths for 5 axis press brakes range from around 4 feet (1.2 meters) to 20 feet (6 meters) or more.

The tonnage rating of a press brake refers to the maximum force that the machine is capable of applying. This is an important consideration when selecting a press brake, as it determines the thickness and type of material that the machine can form. Higher tonnage press brakes can form thicker or harder materials, but may also be more expensive to purchase and operate. Common tonnage ratings for 5 axis press brakes range from around 50 tons to over 1,000 tons.

It's important to select a press brake that is appropriately sized and rated for the specific application. If the press brake is too small or has too low of a tonnage rating, it may not be able to form the desired parts accurately or without damage to the machine. On the other hand, if the press brake is too large or has too high of a tonnage rating, it may be unnecessarily expensive to purchase and operate, and may not be efficient for the specific application.

How much does a 5 axis press brake typically cost and what factors influence the price?

The cost of a 5 axis press brake can vary widely depending on a number of factors, including the size and tonnage rating of the machine, the manufacturer and model, and the specific features and options that are included. In general, 5 axis press brakes tend to be more expensive than traditional press brakes due to the additional complexity and precision of the machine.

Here are some of the factors that can influence the price of a 5 axis press brake:

- Size and tonnage rating: Larger or higher tonnage press brakes will generally be more expensive than smaller or lower tonnage machines.

- Manufacturer and model: Different manufacturers and models of press brakes can have significantly different price points, depending on factors such as the quality of the machine and the features and options that are included.

- Features and options: Press brakes may be available with a range of features and options, such as different types of control systems, automatic tool changers, or special tooling, which can increase the price of the machine.

In general, it's difficult to provide a specific price range for 5 axis press brakes, as the cost can vary so widely depending on the specific factors mentioned above. It may be helpful to consult with a press brake dealer or manufacturer to get a more accurate estimate of the cost for a particular machine.